Low volume, cost-effective engineering component production

We are best known for our ability to produce new engineering components and replacement parts in low volumes and at very economical prices.

For our customers, this means the best of all worlds – quality they can rely on and costs that make sound business sense.

Our secret is having all the right ingredients firmly in place: specialist engineering equipment designed to handle low volume machining, first-class engineering skills and a wealth of experience.

With the capability to machine virtually any type of material – from metal, all grades of stainless steel and cast iron to fibreglass and plastics – we achieve exactly what our customers want on time, every time.

24-hour emergency breakdown service for engineered parts

Wear and tear on equipment and machinery is to be expected, but however well maintenance is planned, components have a habit of breaking down at the worst possible times.

To support our customers, we keep small batches of their regular use engineered components in stock, and provide round the clock supply and fit, ensuring that production downtime is kept to a minimum.

We also make components on an emergency basis, pulling out all the stops to get items completed and fitted as quickly as possible.

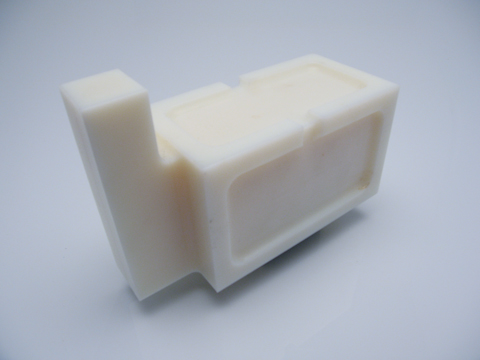

Engineering prototype consultancy and testing

We frequently collaborate with companies that are looking to improve production through new machinery design and application.

We work closely with them at the engineering design stage to make sure that what they are planning is practical and realistic, help them create a prototype, then put it to the test to make sure it functions effectively and fulfils its purpose.

We also conveniently hold stock for customers on site. Read more about the service on our stock-holding page.